Safeguarding the nature: investment into environmental protection increased by 34% over the year

5 November 2021

1406

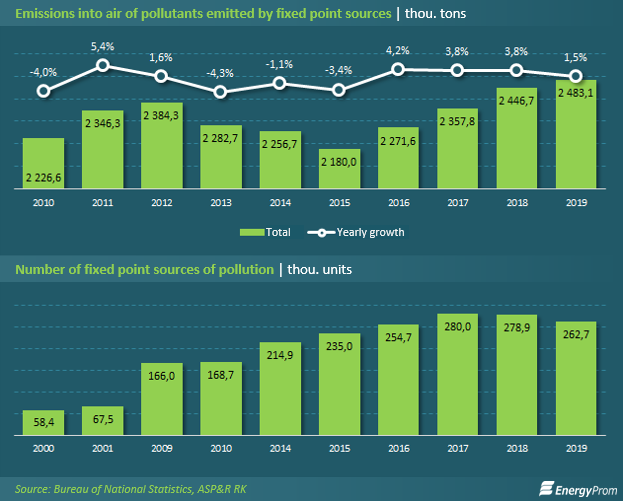

The number of fixed point sources of pollution in 10 years has increased by 58%

Environmental issues are extremely topical all over the world, including in Kazakhstan. A significant part of the population of the Republic of Kazakhstan lives in the area of direct impact by hazardous production factors, the main of which is emissions of pollutants into the air.

In 2019, emissions into the air of pollutants from fixed point sources amounted to 2.5 million tons, i. e. 1.5% more than in the previous year. In general, the increase in emissions has been observed since 2016. Of the total volume of pollutants emitted into the air, 79.6% were gaseous and liquid substances, and 20.4% were solids. Increased air pollution negatively affects human health and ecosystem stability.

In the same year, companies and individual entrepreneurs of the Republic managed to catch and neutralize 93.2% of the total amount of pollutants emitted by all fixed point sources of pollution.

In total, in 2019, there were 262.7 thousand fixed point sources of pollution – 58.2% more than a decade ago.

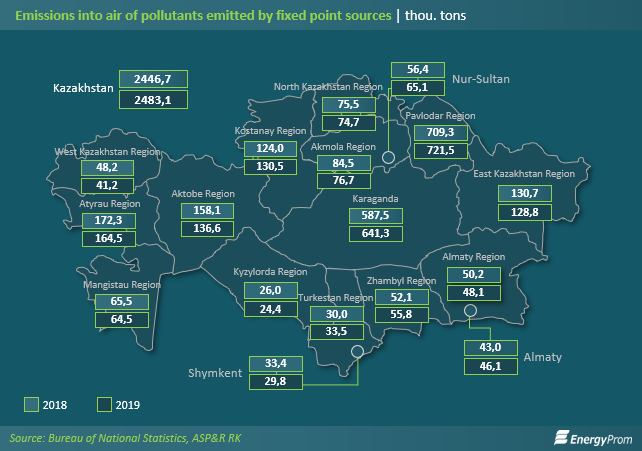

In fact, there is a gradual increase in the number of pollution sources in the country, and at the same time, emissions of pollutants into the air are growing. In the context of regions, the largest volume of pollutant emissions was formed within the territories of Pavlodar (721.5 thou. tons), Karaganda (641.3 thou. tons), Atyrau (164.5 thou. tons), Aktobe (136.6 thou. tons), and East Kazakhstan (128.8 thou. tons) Regions. This is due to the large concentration of industrial enterprises in these regions. As a result, in the above-mentioned regions, actions are being taken to protect the environment, and target indicators have been set. The plan for achieving target indicators of environmental quality includes activities carried out by large industrial enterprises that produce significant impacts on the environment.

So, for example, in Pavlodar Region, at JSC Aluminum of Kazakhstan Pavlodar Aluminum Plant, which is part of ERG (Eurasian Group), work is underway to gradually replace the existing electrostatic precipitators in the furnaces of the sintering shop, yielding a planned environmental effect of reducing dust emissions by 13%. In general, ERG group of companies is implementing an environmental strategy in Pavlodar Region, which will ultimately lead to a 57% reduction in solid emissions, despite the fact that emissions into the environment by Pavlodar Region enterprises are within the limits established by Law. In total, in 2019, investments by the group of companies into environmental activities amounted to 8.9 Billion Tenge, and in 2020-2030 funds in the amount of 134 Billion Tenge are to be allocated.

In turn, in Karaganda Region, in order to involve the public to resolving environmental problems, in 2018, the Council on Environmental Protection was established under the Regional Akim’s chairmanship. The Council is called upon to unite the efforts of the public, business, science, and government agencies in making decisions in the field of ensuring a safe environment and improving the ecological situation in the Region.

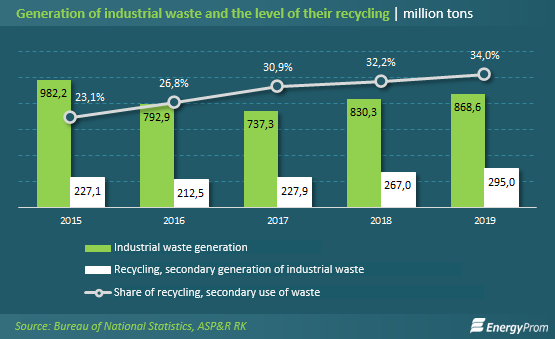

Also, the volume of industrial waste is growing in the country. In 2019, the figure was 868.6 million tons, which is 4.6% more than in 2018. At the same time, the level of waste treatment is also growing. In the same year, the volume of recycled and reused waste reached 295 million tons, which is 10.5% more than in 2018. Whereas the share of recycling is also growing from year to year, which in 2019 amounted to 34% (one year earlier it was 32.2%).

The growth in waste recycling is also often driven by the activities of major industrial companies. Manufacturing enterprises are in constant search of raw materials and technologies that would reduce the cost of production. One of the urgent solutions to this issue is the use of recycled products. For example, in the already mentioned Eurasian Group, a specialized waste recycling company ERG Recycling, established in 2019, operates. The company provides for a full cycle of services related to production waste received from enterprises that are part of ERG.

In 2020, ERG Recycling Co. processed more than 350 thou. tons of waste, including man-made mineral formations. The list of recycled waste includes slags, screenings, cake, dust from gas purifiers, and more. For example: TNK Kazchrome JSC Aktobe Ferroalloy Plant produced and processed 100 thou. tons of refined slag. Of those, 7 thou. tons of low-carbon ferrochrome concentrate were received, which were sent for remelting in the enterprise’s furnaces. The project will continue in 2021. At the same industrial site, there is an opportunity to produce construction materials, for example, wall blocks. The production of construction materials (concrete and concrete products) from waste has been launched, as well as utilizing crust slag – last year, 6 thou. tons of this marketable product were skimmed and collected.

In Kazmarganets Mining Administration, i. e. in TNK Kazchrome JSC Karagand Branch, ERG Recycling is engaged in the processing and sale of manganese ore screenings generated at Vostochny Kamys Deposit site. In Pavlodar Region, the company sells aluminum production slag, carbon-containing waste, bauxite sludge, iron-containing waste, microsilica, limestone screenings, and others.

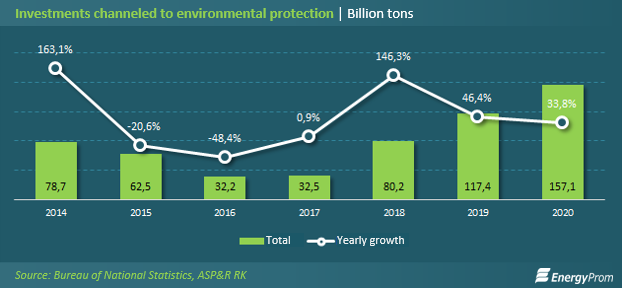

At the end of 2020, investments aimed at environmental protection in Kazakhstan amounted to 157.1 Billion Tenge – 33.8% more than a year earlier (117.4 Billion Tenge). Over the past three years, the amount of investment has been growing by an average of 75.5% per year.

In addition, a new Environmental Code was adopted this year. Its tasks are to ensure a high level of environmental protection through the implementation of state regulation, prevent environmental damage in any form, ensure the elimination of the consequences of environmental damage, strengthen the rule of law and order in the field of environmental protection, ensuring environmental safety, etc.

One of the main points of the Code is “The Polluter Shall Pay” principle. According to this principle, companies that cause harm to the environment must either mitigate it or pay more money to the budget. Under such conditions, companies are interested in preventing negative impact on the environment, and are also stimulated to introduce the most modern available “green” technologies into their production processes.

Note: there are companies in the Republic of Kazakhstan that, even before the adoption of this Code, took actions for the technological modernization of production in order to reduce the negative impact on the environment. For example, in ERG, despite the fact that the volume of particulate matter emissions does not exceed the standards established by the state, they plan to significantly reduce the indicator, to match the standards adopted in the EU. This ambitious initiative will require approximately USD 350 million over a 10-year period. The main areas of activity include the use of advanced gas purification technologies and the conversion of the selected boiler houses to fuel gas.

In general, the action taken by large manufacturing companies, as well as the introduction of “green” technologies and tougher liability for violations of environmental legislation should have a noticeable positive effect in terms of reducing emissions of pollutants in Kazakhstan.

Popular articles

Watch allGas Production Declined, While Prices Jumped 28% Year-on-Year

In January–July of this year, natural gas production in Kazakhstan amounted to 14.8 billion cubic meters, down 10.3% compared with Читать далее...

17 September 2025

3948

Who and why does Kazakhstan’s saiga antelope give trouble?

Experts question the department’s statistics, as well as decisions made at state level regarding saigas In early summer, there Читать далее...

28 June 2022

3543

Which Social Networks and Messengers Do Kazakhstan’s Young People Prefer?

According to the analytical report “Youth of Kazakhstan” for 2024, one of the most common ways young people spend their Читать далее...

9 October 2025

3517

Kazakhstan’s Citizens Are Meat Lovers: Meat and Meat Product Consumption Up by 2%

In January–September of the current year, Kazakhstan produced 57.3 thousand tonnes of fresh or chilled meat from cattle, pigs, sheep, Читать далее...

29 October 2025

2733

Electric Vehicles Accounted for Less Than 1% of All Registered Cars in Kazakhstan

From January to July of this year, 925.8 thousand passenger cars were registered in Kazakhstan, 0.3% more than in the Читать далее...

28 August 2025

2698

“Pirating” in Kazakhstan: 59% of Young People Use Free Platforms to Watch Films and Series

According to the analytical report Youth of Kazakhstan for 2024, one of the most common leisure activities among young people Читать далее...

26 September 2025

2445

Power generation reaches 53.7bn kWh in January-July, up by 1.7% year on year. Gas turbine power plants with a capacity of 100,000 kW worth KZT18.6bn were commissioned in the first half of the year

Electricity tariffs went up by 5.8% year on year in August

16 September 2016

2063

Kazakh oil refineries supplied 73.3% of motor fuel consumed and 97.4% of diesel fuel consumed in the country. Petrol output increased by 10.6% and production of gasoils by 3.6%

The price of the most popular octane-93 petrol increased by 16.4% year on year to KZT125 per litre in July. The price of summer diesel increased by 3.3% year on year to KZT99 per litre

15 September 2016

1873

Industrial enterprises navigate to sustainable development

Major industrial companies’ investments into social and infrastructure projects in 2019 exceeded 140 billion Tenge Kazakhstan has been holding Читать далее...

5 November 2021

1415

Safeguarding the nature: investment into environmental protection increased by 34% over the year

The number of fixed point sources of pollution in 10 years has increased by 58% Environmental issues are extremely Читать далее...

5 November 2021

1406

How Much Do People in Kazakhstan Spend on Medicines?

In the second quarter of this year, household healthcare spending in Kazakhstan averaged 28.8 thousand tenge per household, 6.6% less Читать далее...

25 September 2025

1282

Focus on ESG: the world is confidently switching to green rails and sustainable development principles

In Kazakhstan, only some of the major backbone companies, major market players, and national development institutions are ready to implement Читать далее...

5 November 2021

1276

Output of unrefined and semi-refined gold increased by 21.5% year on year, that of refined gold by 16.5%

Jewellery prices jump by 20.1% year on year on average in Kazakhstan, by 50% in Astana

6 September 2016

1149

Renewable energy generation capacities goes up by 40% year-on-year in Kazakhstan in 1Q2016

Clean energy generation jumps by 130% year-on-year in this period

22 June 2016

1113

Kazakhstan’s crude oil and gas condensate output fall by 3.4% year on year in January-July 2016

In July 2016 crude oil and condensate went down by 0.9% year-on-year

26 September 2016

954